Study on the Smoke and CO Alarm Concentrations to Develop a Smoke & CO Combination Detector

Article information

Abstract

In this study, we studied smoke and CO alarm concentrations to develop a combination detector for both smoke and CO. The derivation of smoke and CO alarm concentrations involved examining CO concentrations by smoke concentration using a sensitivity tester, typically employed for the type approval of photoelectric smoke detectors. Fire alarm and false alarm tests were performed to analyze smoke and CO concentrations further. In the fire alarm test conducted with polyurethane foam, generating black smoke with a reduced light scattering effect in the smoke chamber, no fire alarm was triggered, although the fire alarm concentration of the existing photoelectric smoke detector of sensitivity type 2 was set at 15 %/m. The measured smoke concentration reached only up to 10.2 %/m. Conversely, in the false alarm test with sliced pork belly and mackerel, false alarms occurred as the smoke concentration exceeded 15 %/m. The determined smoke and CO alarm concentrations for the combination detectors were established at 7.5 %/m for smoke (continuously for 10 s) and 15 ppm for CO (continuously for 10 s). Applying these concentrations in subsequent tests revealed an improved performance. In the polyurethane foam fire, where the existing smoke detector failed to operate, a fire alarm was issued at 328 s with the newly derived concentrations. For smoldering wood, the combination detector issued a fire alarm 305 s faster than the existing smoke detector. Furthermore, in the false alarm test with hamburger patty, sliced pork belly, and mackerel, the adaptability of false alarms was enhanced.

1. Introduction

Detectors are crucial devices designed to identify heat, smoke, flames, or combustion products automatically during a fire event and transmit fire signals to a receiver[1]. They are typically categorized into heat, smoke, and flame detectors based on their detection targets. Despite their significance as the primary responders to fires, detectors have often been undervalued owing to frequent false alarms. Specifically, the NFSC 203 revision in 2015 mandated the installation of smoke detectors for early detection in living spaces utilized for sleeping, lodging, and similar purposes among specific firefighting objectives[2]. The replacement of heat detectors with smoke detectors in residential spaces, as stipulated by the revision, has led to an increase in false alarms[3,4]. Smoke detectors can be categorized into ionization and photoelectric types based on their functionalities, and the majority of smoke detectors installed in corridors, living rooms, and stairs are photoelectric ones. These detectors utilize an IR LED and a photocell in the smoke chamber, operating by detecting changes in light flow into the photocell caused by light scattering when smoke of a certain concentration or higher enters the chamber during a fire. However, when aerosols causing light scattering are introduced instead of smoke, the limitations of distinguishing false alarms arise with a single smoke sensor. This makes photoelectric smoke detectors susceptible to malfunctions triggered by common residential factors, such as humidity, cooking smoke, water vapor, and shower steam. False alarms from these detectors are often considered inevitable; however, in various fire-related incidents, human casualties and property damage have been exacerbated by incorrect actions, such as turning off the receiver and disabling alarm outputs owing to frequent false alarms[5]. To address false alarms, the current approach involves utilizing existing type approval certification targets, such as the heat and smoke combination type. However, this method raises concerns as heat and smoke detectors have different detection targets, potentially causing delayed fire detection when alarms are triggered simultaneously. Consequently, most detectors are certified under the OR condition rather than the AND condition to prevent early fire detection failure, increasing the risk of false alarms under two conditions (heat or smoke). For photoelectric smoke detectors, the operational delay owing to reduced light scattering characteristics caused by fires, particularly with polyurethane foam and flammable liquids generating black smoke, is more worrisome than false alarms. Various composite sensors have been investigated to enhance the adaptability of photoelectric smoke detectors to fire detection and prevent false alarms. A notable example is the development of smoke and CO combination detectors utilizing CO sensors. However, this solution faces challenges in the fire protection market owing to the absence of a standardized test method and alarm concentration criteria to verify the performance of CO sensors for fire detection.

In this study, we examined CO concentrations by smoke concentration using a sensitivity tester, commonly employed for the type approval of photoelectric smoke detectors. The objective was to derive smoke and CO alarm concentrations for smoke and CO combination detectors. Subsequently, fire alarm and false alarm tests were conducted to analyze smoke and CO concentrations.

2. Experiment

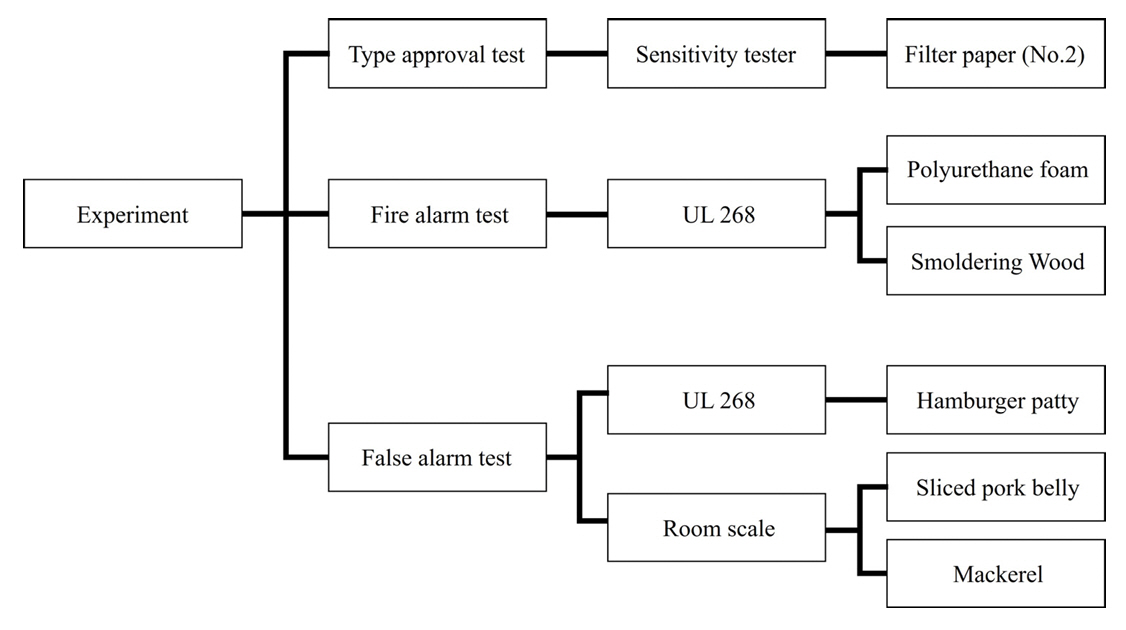

Figure 1 shows the experimental configuration to derive smoke and CO alarm concentration standards for smoke and CO combination detectors. In the experiment, CO concentrations by smoke concentration were examined first using a sensitivity tester, which is used for the type approval of photoelectric smoke detectors, and fire alarm and false alarm tests were conducted to analyze smoke and CO concentrations under fire and non-fire conditions. The fire alarm test was conducted using smoldering wood and polyurethane foam fire, which are specified in UL 268. The false alarm test was conducted at a real-scale false alarm test site using sliced pork belly and mackerel, which are highly likely to cause false alarms during cooking at homes in Korea, in addition to the hamburger patty test, which is the UL 268 cooking nuisance test.

Figure 2 shows the experimental samples used to measure the smoke and CO concentrations in each test. The smoke concentration was measured in real time using an analog smoke detector (0 to 20.4 %/m) from company T, which received type approval. For accurate CO concentration measurement, the CO concentration was measured in real time using a combustion gas analyzer (Wohler A550, USA).

2.1 CO measurement by smoke concentration according to the type approval standards

In accordance with Article 19 of the Technical Standards for Type Approval and Product Inspection of Detectors[1], a sensitivity test was conducted using the photoelectric smoke detector sensitivity tester shown in Figure 3[3]. The wind speed inside the sensitivity tester was maintained at 30 cm/s according to the test standards, and filter paper No. 2 was used as a smoke sample. The smoke concentration was measured using an optical density meter (ODM) attached to the smoke detector sensitivity tester. The smoke concentrations were set to 7.5 %/m (sensitivity type 1), 15 %/m (type 2), and 22.5 %/m (type 3), which are the operating concentrations. In addition, the nonoperating concentration was set to 5 %/m, which is the nonoperating concentration of sensitivity type 2 smoke detectors, because sensitivity type 2 is used for most of the smoke detectors in Korea. At each set concentration, the operating test was conducted for 30 s and the nonoperating test was conducted for 300 s in accordance with the test standards. The maximum CO concentrations for each smoke concentration were measured using the combustion gas analyzer.

2.2 Fire alarm test

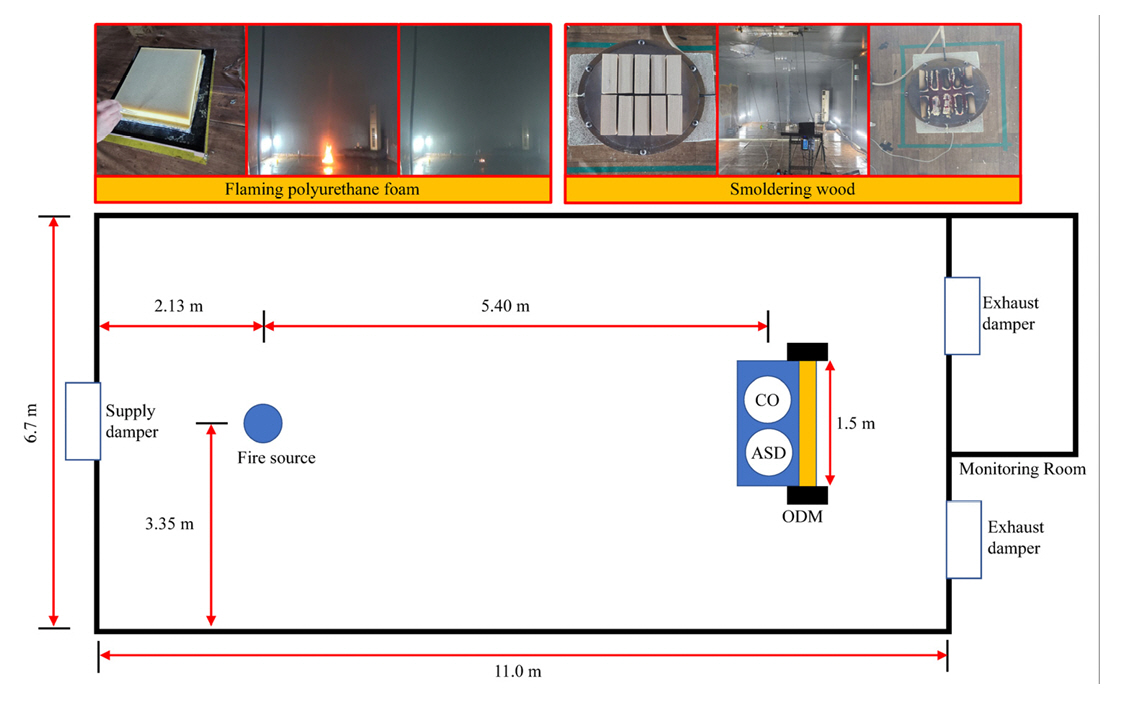

To derive smoke and CO alarm concentrations for smoke and CO combination detectors in the event of a fire, the fire alarm test was conducted for polyurethane foam fire, which caused the nonoperation of photoelectric smoke detectors in the existing UL 268 research results, and smoldering wood with the high adaptability of CO owing to smoldering[6,7]. The test with polyurethane foam fire and smoldering wood was conducted under the same test standards in the fire test site with the size specified in UL 268 shown in Figure 4. Each fire source was located at a distance of 2.13 m from the wall, and an analog smoke detector to measure the smoke concentration (hereafter, ASD) and a combustion gas analyzer to measure the CO concentration (hereafter, CO sensor) were installed on the ceiling at a distance of 5.4 m from the fire source. The test was conducted after preprocessing according to each test standard. As for the analysis of the results, the real-time smoke and CO concentrations were analyzed using the smoke profile and appropriate data presented in UL 268 based on the ODM installed according to the UL 268 standard[8]. After preparing a container of size 368 × 432 × 76 mm using aluminum foil, a polyurethane foam (density 25 ± 0.8 kg/m3) sample was placed on top of marble, which was an incombustible tile at a height of 70 mm from the floor. The sample was then ignited after absorbing 5 mL of denatured alcohol in the corner, and the test was conducted until 540 s when the flame of the polyurethane foam was completely extinguished. Ten wood (Pinus ponderosa) samples of size 76.2 × 19.1 × 25.5 mm were placed on the hot plate at a height of 200 mm from the floor. The temperature was increased by 60.7 ℃/min (initial temperature 23 ± 2 ℃) to reach 205 ℃ within 180 s. After 180 s, it was increased by 3.2 ℃/min and the test was continued until 4000 s[8].

2.3 False alarm test

To present smoke and CO alarm concentrations for smoke and CO combination detectors in the event of a false alarm, the false alarm test was conducted using sliced pork belly and mackerel at a real-scale false alarm test site in addition to the UL 268 hamburger patty test. Figure 5 shows the schematic of the hamburger patty test. In accordance with the UL 268 standard, a temporary wall was installed in the fire test site to create a false alarm test site of size 9.35 × 6.7 × 3.0 m. The height from the top of the oven to the ceiling was 1.54 m. The ASD and CO sensor were installed on the ceiling at a distance of 3.05 m from the oven, and the test was conducted after preprocessing according to the test standard. After preheating the oven to 270 ℃, three hamburger patties (100 to 120 g per piece) were placed inside the oven. After closing the door and applying heat for 300 s by raising the temperature to 320 ℃, the oven door was opened by 11.5 cm for smoke release. Heat was then continuously applied for 1200 s. As for the analysis of the results, the real-time smoke and CO concentrations were analyzed using the smoke profile and appropriate data presented in UL 268 based on the ODM installed according to the UL 268 standard.

Figure 6 shows the schematic of the false alarm test with sliced pork belly and mackerel. The test was conducted in a real-scale false alarm test site of size 2.5 × 4.0 × 2.5 m. The ASD and CO sensor were installed on the ceiling at a distance of 3 m from the frying pan (diameter: 28 cm) on top of the gas stove to analyze real-time smoke and CO concentrations. In the sliced pork belly test, frozen sliced pork belly (total weight: 300 ± 10 g) was evenly distributed on the frying pan, and the output of the gas stove was set to the maximum. The test was conducted for 1080 s considering the time that the pork belly oil does not catch fire through a preliminary test. In the mackerel test, two pieces of frozen mackerel (total weight: 300 ± 10 g) were evenly distributed on the frying pan, and the output of the gas stove was set to the maximum after applying cooking oil (30 g). The test was conducted for 1080 s as in the pork belly test.

3. Experiment Results

3.1 CO measurement results by smoke concentration according to the type approval standards

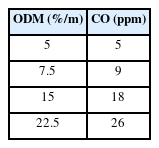

Table 1 presents the results of measuring the maximum CO concentration by smoke concentration in the smoke detector sensitivity tester. The maximum CO concentration was 5 ppm at 5 %/m, which is the nonoperating concentration of smoke detector sensitivity type 2. It was 9 ppm at 7.5 %/m, which is the operating concentration of smoke detector sensitivity type 1; 18 ppm at 15 %/m, which is the operating concentration of sensitivity type 2; and 26 ppm at 22.5 %/m, which is the operating concentration of sensitivity type 3.

3.2 Fire alarm test results

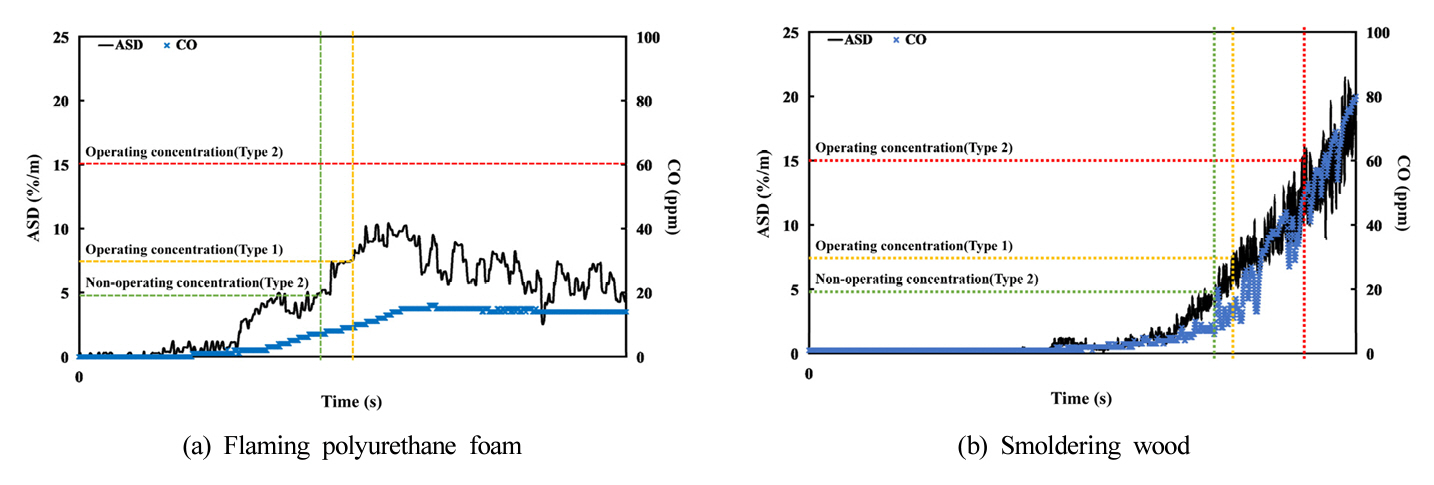

Figure 7(a) shows the smoke and CO concentrations measured through the ASD and CO sensor during the fire alarm test with polyurethane foam. At 238 s, the smoke concentration of the ASD reached 5 %/m, which is the nonoperating concentration of sensitivity type 2. In this instance, the CO concentration was measured to be 7 ppm. At 268 s, the smoke concentration of the ASD reached 7.5 %/m, which is the operating concentration of sensitivity type 1, and the CO concentration was measured to be 9 ppm. At 293 s, the smoke concentration of the ASD reached a maximum of 10.2 %/m and the CO concentration was measured to be 11 ppm. The maximum CO concentration was measured to be 16 ppm at 346 s. In the results of the fire alarm test with polyurethane foam, no fire alarm was issued as the smoke concentration measured through the ASD could not reach 15 %/m, which is the operating concentration of sensitivity type 2. As in previous studies, smoke detectors of sensitivity type 2 are mostly used in Korea to prevent malfunction in everyday life. However, photoelectric smoke detectors that use the light scattering method have high adaptability to white smoke with high scattering characteristics owing to active light scattering, but they cannot reach the alarm concentration of sensitivity type 2 in black smoke with high absorption characteristics owing to reduced light scattering[9].

Figure 7(b) shows the smoke and CO concentrations measured through the ASD and CO sensor during the fire alarm test with smoldering wood. At 2973 s, the smoke concentration of the ASD reached 5 %/m. In this instance, the CO concentration was measured to be 8 ppm. At 3107 s, the smoke concentration of the ASD reached 7.5 %/m and the CO concentration was measured to be 12 ppm. At 3623 s, the smoke concentration of the ASD reached 15 %/m, which is the operating concentration of sensitivity type 2, and the CO concentration was measured to be 49 ppm. The maximum smoke concentration was measured to be 20.4 %/m, which was the maximum value that the ASD could measure, at 3919 s. The maximum CO concentration was measured to be 80 ppm at 4000 s. The fire alarm concentrations were exceeded, and fire alarms were issued owing to active light scattering in the smoldering wood, which generated white smoke, unlike the polyurethane foam fire, which generated black smoke. The CO concentration was also measured to be more than five times higher in the smoldering wood compared with the flaming polyurethane foam.

3.3 False alarm test results

Figure 8 shows the smoke and CO concentrations measured through the ASD and CO sensor during the false alarm test with a hamburger patty. At 1003 s, the smoke concentration of the ASD reached 5 %/m. In this instance, the CO concentration was measured to be 4 ppm. At 1069 s, the smoke concentration of the ASD reached 7.5 %/m and the CO concentration was measured to be 5 ppm. The maximum smoke concentration measured through the ASD was 11.7 %/m at 1330 s. As it could not reach 15 %/m, which is the alarm concentration of sensitivity type 2, no fire alarm was issued, indicating suitability for the UL 268 cooking nuisance test. The maximum CO concentration was measured to be 7 ppm at 1148 s.

Figure 9(a) shows the smoke and CO concentrations measured through the ASD and CO sensor during the false alarm test with sliced pork belly. At 579 s, the smoke concentration of the ASD reached 5 %/m. In this instance, the CO concentration was measured to be 0 ppm. At 616 s, the smoke concentration of the ASD reached 7.5 %/m and the CO concentration was measured to be 0 ppm. At 699 s, the smoke concentration of the ASD reached 15 %/m and a fire alarm was issued. In this instance, the CO concentration was measured to be 1 ppm. The maximum smoke concentration was measured to be 20.4 %/m, which was the maximum value that the ASD could measure, at 744 s, and the maximum CO concentration was measured to be 3 ppm at 892 s. Figure 9(b) shows the smoke and CO concentrations measured through the ASD and CO sensor during the false alarm test with mackerel. At 506 s, the smoke concentration of the ASD reached 5 %/m. In this instance, the CO concentration was measured to be 0 ppm. At 540 s, the smoke concentration of the ASD reached 7.5 %/m, and the CO concentration was measured to be 1 ppm. At 648 s, the smoke concentration of the ASD reached 15 %/m, and a fire alarm was issued. In this instance, the CO concentration was measured to be 2 ppm. The maximum smoke concentration was measured to be 20.4 %/m, which was the maximum value that the ASD could measure, at 731 s, and the maximum CO concentration was measured to be 4 ppm at 1024 s.

In the false alarm test with the hamburger patty in accordance with the UL 268 test standard, which is the overseas standard, no false alarm was issued because the smoke concentration of sensitivity type 2 was not reached. In the case of the false alarm test with sliced pork belly and mackerel, which have the highest false alarm possibility during cooking in Korea, fire alarm concentrations were reached and false alarms were issued because the amount of smoke generated was larger than that for the hamburger patty and the smoke concentration increased in the space even though the space became smaller compared with the UL 268 test site.

3.4 Discussion on smoke and CO alarm concentrations

Summarizing the above results, in the polyurethane foam fire, which generated black smoke in the fire alarm test, the fire could not be detected using the existing smoke sensor alone because the smoke concentration measured in the smoke chamber (up to 10.2 %/m) could not reach 15 %/m, which is the alarm concentration of sensitivity type 2, owing to the reduced light scattering of the photoelectric smoke detector. In the false alarm test with sliced pork belly and mackerel, false alarms occurred as the smoke concentration exceeded 15 %/m, confirming that false alarms cannot be prevented using the existing single smoke sensor alone.

Therefore, when smoke and CO alarm concentrations are examined for the development of a smoke and CO combination detector, the results in Table 2 can be derived. When only the smoke concentration of 15 %/m, i.e., the existing fire alarm method, was applied, it was observed to be unsuitable for polyurethane foam, sliced pork belly, and mackerel. For an improvement, the CO alarm concentration was set to 15 ppm. This is because the maximum concentration of CO in the false alarm test was 7 ppm and a maximum value of 9 ppm was measured at 7.5 %/m, which is the concentration of sensitivity type 1 according to the type approval test standard. Thus, a value higher than these values was primarily considered as a fire alarm value. In the fire alarm test, the lowest CO concentration was measured in the polyurethane foam fire. In this instance, the maximum concentration of CO was 16 ppm. Accordingly, the CO alarm concentration was set to 15 ppm considering deviations to detect fires rapidly and minimize false alarms. When smoke 15 %/m and CO 15 ppm were applied to improve the existing fire alarm method, the performance of false alarms was improved for sliced pork belly and mackerel because no false alarm occurred, but they were still inappropriate for polyurethane foam fire. In the case of fire detectors, the adaptability of fire alarms must be considered before that of false alarms. Thus, the existing sensitivity standards need to be changed. In other words, a detection method faster than the existing method is required for smoke and CO combination detectors because fire alarms need to be issued by detecting two or more factors rather than a single factor. Therefore, a concentration of 7.5 %/m, which enables earlier detection than a concentration of 15 %/m, was applied. As the smoke concentration for alarms decreased, an accumulation time of 10 s was provided to minimize the possibility of false alarms under conditions other than those of this study. This is because the smoke residence time is approximately 5 s when smoke flows into the smoke chamber under artificial false alarm conditions, such as cigarette smoke. In other words, the continuous introduction of smoke for 10 s or longer can be judged to be a sign of fire.

Finally, the smoke and CO alarm concentration criteria for the development of a smoke and CO combination detector are as follows. Fire alarms were set to be issued when a smoke concentration of 7.5 %/m or higher and a CO concentration of 15 ppm or higher were continuously measured for 10 s (10 s accumulation function) (AND condition). The derived smoke and CO alarm concentration criteria were observed to be suitable when applied to the fire alarm and false alarm test results. When these alarm criteria were applied to the above test results, a fire alarm was issued at 328 s in the polyurethane foam fire for which the existing smoke detector did not operate. In the case of the smoldering wood, a fire alarm was issued 305 s faster than the existing smoke detector, confirming that adaptability to fire and false alarms was significantly improved.

4. Conclusions

In this study, smoke and CO alarm concentrations were investigated to develop a smoke and CO combination detector, and the following conclusions were drawn.

1. When the maximum CO concentration by smoke concentration was measured according to the type approval standards, the results were 5 ppm at 5 %/m, 9 ppm at 7.5 %/m, and 18 ppm at 15 %/m.

2. In the fire alarm test with the polyurethane foam fire, no fire alarm was issued because the maximum smoke concentration (10.2 %/m) could not reach 15 %/m, which is the operating concentration of smoke detector sensitivity type 2, and the maximum CO concentration was measured to be 16 ppm. In the case of the smoldering wood, a fire alarm was normally issued as the measured smoke concentration exceeded 15 %/m, and the maximum CO concentration was measured to be 80 ppm.

3. In the false alarm test with the hamburger patty, no false alarm occurred because the maximum smoke concentration (11.7 %/m) could not reach the fire alarm concentration (15 %/m), and the maximum CO concentration was measured to be 7 ppm. However, in the case of the sliced pork belly and mackerel, false alarms occurred because the measured smoke concentration exceeded 15 %/m, and the maximum CO concentrations were measured to be 3 and 4 ppm, respectively.

4. When 7.5 %/m for smoke (continuously for 10 s) and 15 ppm for CO (continuously for 10 s) were applied as smoke and CO alarm concentrations for the development of a smoke and CO combination detector, the adaptability of fire detection was improved for both the polyurethane foam and smoldering wood in the fire alarm test. The adaptability of false alarms was also improved for the hamburger patty, sliced pork belly, and mackerel in the false alarm test.

The presented smoke and CO alarm concentration criteria are suitable for the experimental conditions of this study and can improve fire detection adaptability to black smoke. Although they cannot prevent all false alarms, they are expected to be highly adaptable to animal fats, such as sliced pork belly. As there is no test standard for CO fire alarms in Korea, the fire alarm and false alarm test results of this study are expected to be used as basic data for the development of smoke and CO combination detectors and the preparation of standards for them.

Notes

Conflicts of Interest

The authors declare no conflict of interest.

Acknowledgements

This study was supported by the National Fire Agency of the Republic of Korea (20016764).