|

|

- Search

| Int J Fire Sci Eng > Volume 37(1); 2023 > Article |

|

Abstract

Previous studies on the strength degradation of concrete subjected to high temperatures were analyzed. To analyze the effect of the coarse-aggregate type on strength degradation, data from previous studies were collected, and the coarse aggregate used, physical properties of the aggregate, and heating conditions were analyzed. The concrete types were classified into normal, heavyweight, and lightweight concrete. Their high-temperature characteristics were analyzed and evaluated according to the mixed coarse aggregate. Finally, the correlations derived from the analysis results were compared with the CEB Code. The analysis results were different for different concrete and coarse-aggregate types, and different tendencies from the CEB Code were observed.

Cement-based materials have been continuously produced and developed as they are recognized as excellent construction materials with regard to workability, safety, and economic feasibility [1]. In particular, concrete, which is produced by mixing cement with a large amount of aggregate, has been used as a material with excellent fire resistance performance that maintains structural and material stability when subjected to high temperatures from fires inside and outside buildings [2]. Concrete can maintain structural safety when exposed to high temperatures over a relatively short period; however, its durability rapidly decreases with long-term exposure [3].

When concrete is subjected to high temperatures, strength degradation occurs owing to the high-temperature characteristics of its material constituents, followed by changes in the internal structure. The free water and bound water remaining in concrete evaporate in the temperature range of 100-200 Ōäā, and calcium hydroxide (Ca(OH)2) is decomposed at a temperature of approximately 300 Ōäā or higher. The higher temperature range represents a chemical decomposition stage, in which C-S-H gel and calcium carbonate are decomposed. At a temperature of approximately 1,000 Ōäā or higher, concrete melts. Concrete is also significantly affected by the aggregate that it contains. When concrete is subjected to high temperatures, the aggregate exhibits thermal expansion, whereas cement-based materials exhibit thermal contraction (see Table 1) [4]. Owing to such different thermal properties, microcracks and macrocracks occur in concrete.

Through the analysis of existing experimental data on the high-temperature characteristics of concrete, various associations and committees, such as CEB/FIP, CEN, ACI, and ASCE, have proposed standard codes (see Figure 1) [5-10]. For these codes, experiments have been performed by various researchers because it is necessary to fully examine high-temperature characteristics along with the development of various materials on a regular basis.

Therefore, in this study, the high-temperature characteristics of concrete were analyzed with respect to different variables through the collection and classification of experimental data from studies conducted in the past 10 years. The studies were classified according to the type of coarse aggregate contained in the concrete, and the analysis results were compared with the CEB/FIP Code.

Table 2 presents the analysis scope and plan of this study [11-26]. The concrete types for analysis were set as normal, heavyweight, and lightweight concrete. Classification was then performed according to the type of coarse aggregate. For normal concrete, the aggregate types were set as granite and limestone. In the case of lightweight and heavyweight aggregates, various types of aggregates were mixed in previous studies. Because few studies were conducted on a single aggregate type, an integrated analysis was conducted. The residual compressive strength was set as an analysis item. The residual compressive strength was analyzed together with the CEB Code (Siliceous) for normal and heavyweight concrete and the CEB (Lightweight) Code for lightweight concrete.

Figure 2 presents the analysis method of this study. First, previous domestic and overseas studies on the hightemperature characteristics of concrete were investigated and collected. They were classified by the concrete type (normal, lightweight, or heavyweight) and then by the coarse-aggregate type. From the classified studies, residual compressive strength data were analyzed and summarized. Finally, strength degradation models for concrete subjected to high temperature were proposed according to the coarse-aggregate type.

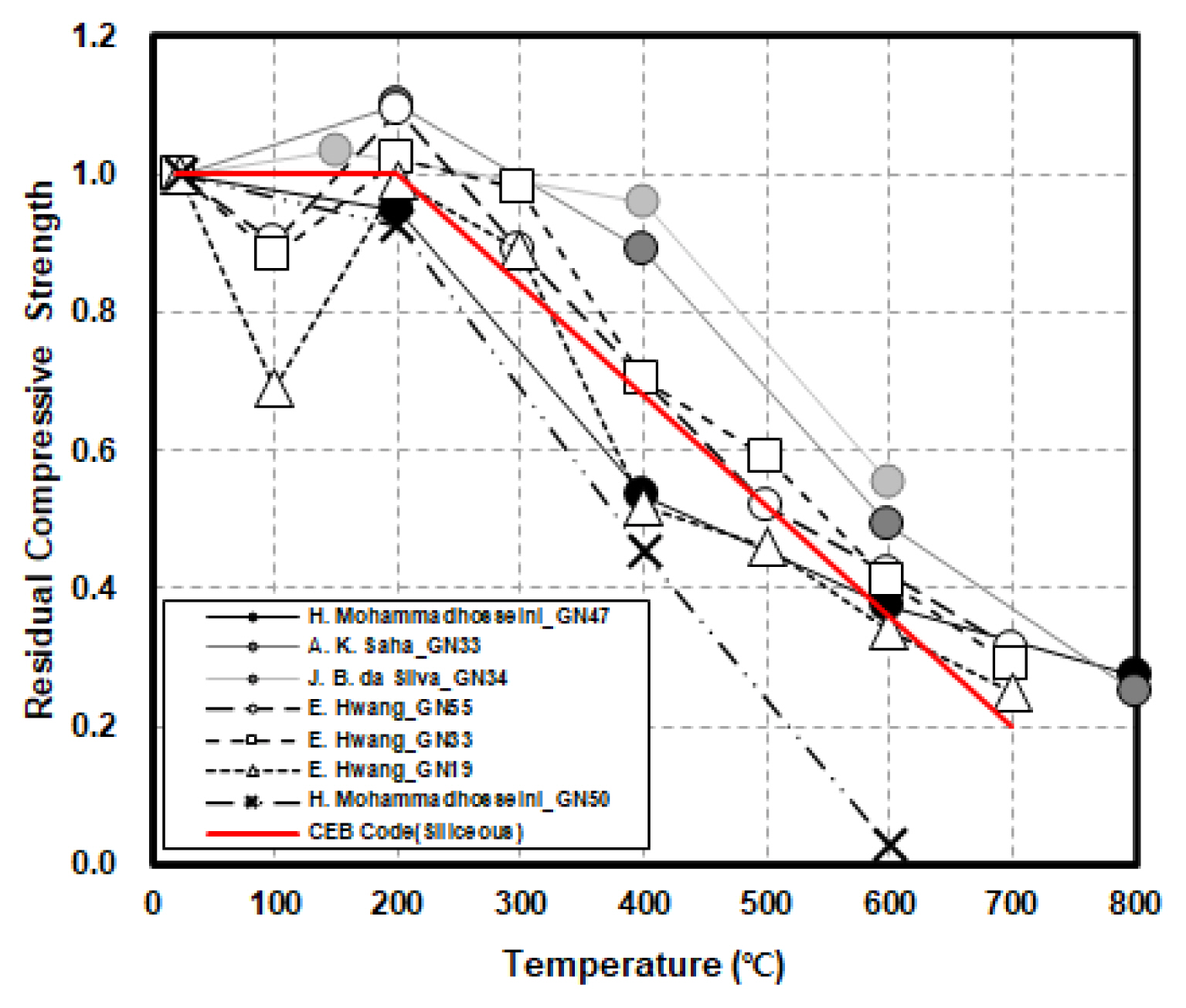

Figure 3 shows the results for concrete mixed with granite aggregates. Overall, slight strength degradation was observed at approximately 100 Ōäā. This is a stage in which the formation of voids begins as the free water and surface water inside concrete evaporate [11-14,23]. Subsequently, a slight increase in strength was observed at 200 Ōäā. This phenomenon was also reported in previous studies on the high-temperature characteristics of concrete. In the 200-300 Ōäā range, the effects of the forced hydration reaction, aggregate expansion, and water vapor pressure due to water evaporation were reported [27-32].

Thereafter, the strength continuously decreased, and most of the experimental results exhibited a tendency similar to that of the CEB Code. However, H. Mohammadbosseini et al. [11] reported a very low residual strength compared with the CEB Code. This appears to be due to the high heating rate (20 Ōäā/min) compared with other experiments. Conversely, A. K. Saha and J. B. da Silva et al. [12,13] reported higher residual strengths compared with the CEB Code and other experiments. E. Hwang et al. [14] reported a relatively low residual strength despite the water/binder (W/B) ratio being similar to those of the two aforementioned studies. This appears to be due to the difference in aggregate density. However, the residual strength was higher than those of the CEB Code and the remaining experiments.

Figure 4 shows the results for concrete mixed with limestone aggregates. A tendency similar to that of Figure 3 was observed in the temperature range below approximately 200 Ōäā, but the overall results exceeded the CEB Code in the higher temperature range. M. Saridemir et al. [16] reported a higher residual strength compared with the CEB Code and other studies. This appears to be due to the distribution and fineness modulus of the aggregates in various sizes. Figure

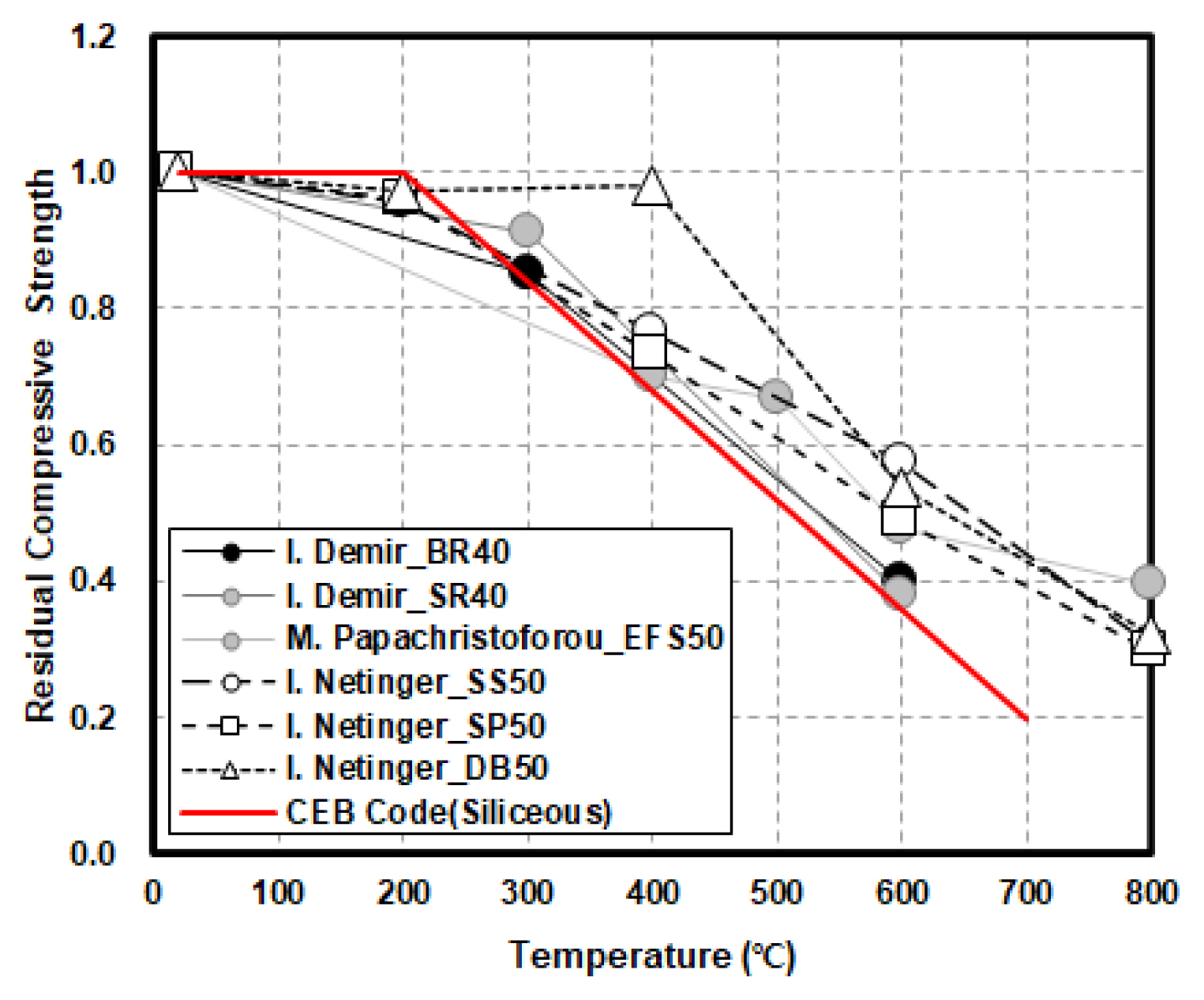

Figure 5 shows the results for concrete mixed with heavyweight aggregates. Most of the results exceeded the CEB Code. This appears to be due to the high density of the heavyweight aggregate. I. Demir et al. [17] reported a low residual strength even though the W/B ratio was lower than those of other studies. The heating rate was not clearly reported, except in the case of I. Demir et al., and it is judged that different heating conditions among the laboratories caused differences. Fewer studies on concrete mixed with heavyweight aggregates were collected compared with the other aggregate types. Thus, additional experiments are required for accurately determining the high-temperature characteristics of heavyweight aggregates.

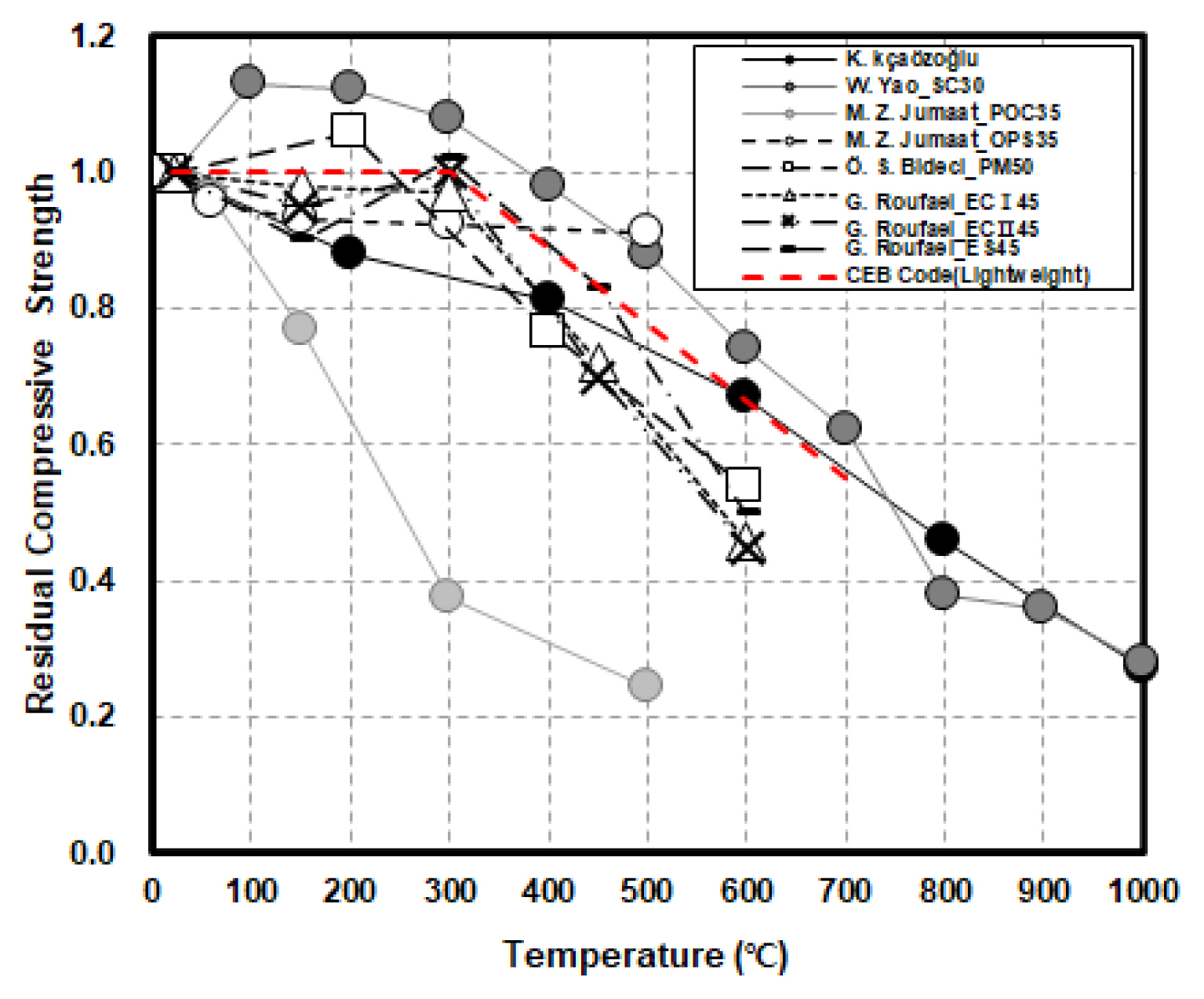

Figure 6 shows the results for concrete mixed with lightweight aggregates. Except for the studies of W. Yao and ├¢. S. Bideci et al. [24,26], a lower residual strength compared with the CEB Code was observed in the temperature range below 300 Ōäā. W. Yao et al. [24] added shale ceramsiteŌĆöa type of sedimentary rockŌĆöand reported a dense structure compared with an ordinary aggregate. Scanning electron microscopy results indicated few defects, such as surface cracks and voids, at room temperature (20 Ōäā). In addition, phenomena such as cracks and voids were not clearly observed until the temperature reached 400 Ōäā. They reported that the internal structure was maintained despite the presence of defects when the shale ceramsite was heated to a temperature higher than 1,000 Ōäā. Such hightemperature characteristics appear to have contributed to the higher residual strength compared with the experimental results for other lightweight aggregates.

K. k├¦a├Čzo─¤lu et al. [23] reported a relatively low residual strength until the temperature reached 400 Ōäā. At higher temperatures, however, the residual strength was similar to that of the CEB Code and higher than other experimental results. The aggregate mixed by K. k├¦a├Čzo─¤lu et al. had a density of approximately 430 kg/m3, which was the lowest aggregate density among the analyzed studies on lightweight aggregate concrete. It appears that a high residual strength was observed at a high temperature because the thermal expansion of the aggregate was relatively small owing to the relatively high porosity; thus, the interfacial transition zone (ITZ) of the aggregate and paste was improved. M. Z. Jummat et al. [25] added oil palm shell (OPS). They reported that a very low residual strength was observed under the influence of the severe thermal contraction of the aggregate.

Figure 7 shows the trendlines of concrete subjected to high temperatures for different aggregate types. For normal and heavyweight concrete, a low residual strength was observed compared with the CEB Code (Siliceous) up to approximately 200 Ōäā. For lightweight aggregates, however, a high residual strength was observed. At 300 Ōäā, except for concrete mixed with lightweight aggregates, a residual strength similar to or higher than that of the CEB Code (Siliceous) was observed. When limestone and heavyweight aggregate were mixed, approximately 6.8% and 7.1% higher residual strengths were observed. When lightweight aggregate was mixed, a residual strength approximately 4.3% lower than that of the CEB Code (Lightweight) was observed.

In the temperature range higher than 400 Ōäā, the residual strengths of normal and heavyweight concrete exceeded those of the CEB Code (Siliceous). For lightweight concrete, a lower residual strength compared with the CEB Code (Lightweight) was observed. As the temperature increased, the difference from the CEB Code tended to gradually increase for all levels. The results for the granite aggregates were the most similar to the CEB Code (Siliceous), with a residual strength approximately 5.3% higher. For the limestone aggregates, the residual strength was approximately 17.3% higher. The heavyweight aggregates exhibited the largest difference from the CEB Code (Siliceous), with a residual strength approximately 35.2% higher. For the lightweight aggregates, the residual strength was approximately 17.4% lower than that of the CEB Code (Lightweight).

In the analysis results of this study, normal concrete mostly exhibited a higher residual strength compared with the CEB Code at all temperatures. This appears to be due to the development of chemical and production technologies compared with previous cement. Concrete mixed with heavyweight aggregates exhibited a large difference from the CEB Code. It is deemed necessary to develop a strength degradation model for heavyweight concrete through additional experiments. In addition, concrete mixed with lightweight aggregates exhibited a lower residual strength compared with the CEB Code, and this needs to be considered during the design process.

Previous studies on the strength degradation characteristics of concrete subjected to high temperature for different types of coarse aggregates were analyzed. The analysis results are summarized as follows.

1) At all levels, slight strength degradation was observed until the temperature reached approximately 200 Ōäā, and the strength was lower than that of the CEB Code. A slight increase in strength was observed at approximately 300 Ōäā. Subsequently, continuous strength degradation was observed.

2) Concrete mixed with granite and limestone aggregates mostly exhibited higher residual strengths compared with the CEB Code in the temperature range higher than 300 Ōäā.

3) For concrete mixed with heavyweight aggregates, the residual strength exceeded the CEB Code and exhibited the largest difference. Because studies on the high-temperature characteristics of heavyweight aggregates are insufficient compared with the other aggregate types, continuous research is required. It is also deemed necessary to develop a strength degradation model for heavyweight aggregates.

4) For lightweight aggregates, the residual strength was lower than that of the CEB Code, indicating that conservative design is required considering the characteristics (e.g., low stiffness) and safety of lightweight aggregates.

Notes

Author Contributions

Conceptualization, H.C. and T.L.; methodology, H.C. ; software, W.K and K.J..; validation, H.C. and T.L. ; formal analysis, W.K.; investigation, W.K.; resources, H.C.; data curation, W.K.; writingŌĆĢoriginal draft preparation, W.K.; writingŌĆĢreview and editing, H.C. ; visualization, T.L.; supervision, H.C.; project administration, T.L.; funding acquisition, K.J. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2022R1F1A1073333).

Table┬Ā1

Coefficient of Thermal Expansion for Different Types of Rock

Table┬Ā2

Analysis Plan

References

1. V Kodur, ŌĆ£Properties of Concrete at Elevated TemperaturesŌĆØ, ISRN Civil Engineering, (2014), pp. 468510(2014), https://doi.org/10.1155/2014/468510.

2. B Georgali and P. E. Tsakiridis, ŌĆ£Microstructure of Fire-Damaged Concrete. A Case StudyŌĆØ, Cement and Concrete Composites, Vol. 27, No. 2, pp. 255-259 (2005), https://doi.org/10.1016/j.cemconcomp.2004.02.022.

3. Y. Lin, C. Hsiao, H. Yang and Y. Lin, ŌĆ£The Effect of Post-Fire-Curing on Strength-Velocity Relationship for Nondestructive Assessment of Fire-Damaged Concrete StrengthŌĆØ, Fire Safety Journal, Vol. 46, No. 4, pp. 178-185 (2011), https://doi.org/10.1016/j.firesaf.2011.01.006.

4. S. Park, H. Yim and H. Kwak, ŌĆ£Effects of Post-Fire Curing Conditions on the Restoration of Material Properties of Fire-Damaged ConcreteŌĆØ, Construction and Building Materials, Vol. 99, pp. 90-98 (2015), https://doi.org/10.1016/j.conbuildmat.2015.09.015.

5. Comit├® Euro-international Du B├®ton, Fire Design of Concrete Structures, in Accordance with CEB/FIP Model Code 90, (1991).

6. British Standard Institute, Eurocode 2: Design of Concrete Structures - Part 1.2: General Rules - Structural Fire Design, BS EN. 1992-1-2 (2004).

7. American Concrete Institute, ŌĆ£Guide for Determining the Fire Endurance of Concrete ElementsŌĆØ, ACI: 2016R-89R, (1989).

8. American Society of Civil Engineers (ASCE), ŌĆ£Structural Fire Protection. Committee on Fire Protection, Structural DivisionŌĆØ, ASCE, New York, NY, USA (1992).

9. Concrete Association of Finland, ŌĆ£High Strength Concrete Supplementary Rules and Fire DesignŌĆØ, RakMK B4, (1991).

10. Architectural Institute of Japan, Guide Book for Fire-Resistive Performance of Structural Materials, (2017).

11. H. Mohammadhosseini and J. M. Yatim, ŌĆ£Microstructure and Residual Properties of Green Concrete Composites Incorporating Waste Carpet Fibers and Palm Oil Fuel Ash at Elevated TemperaturesŌĆØ, Journal of Cleaner Production, Vol. 144, pp. 8-21 (2017), https://doi.org/10.1016/j.jclepro.2016.12.168.

12. A. K. Saha, P. K. Sarker and S. Majhi, ŌĆ£Effect of Elevated Temperatures on Concrete Incorporating Ferronickel Slag as Fine AggregateŌĆØ, Fire and Materials, Vol. 43, No. 1, pp. 8-21 (2019), https://doi.org/10.1002/fam.2664.

13. J. B. da Silva, M. Pepe and R. D. T. Filho, ŌĆ£High Temperatures Effect on Mechanical and Physical Performance of Normal and High Strength Recycled Aggregate ConcreteŌĆØŌĆØ, Fire Safety Journal, Vol. 117, pp. 103222No. 2020, https://doi.org/10.1016/j.firesaf.2020.103222.

14. E. Hwang, G. Kim, G. Choe, M. Yoon, N. Gucunski and J. Nam, ŌĆ£Evaluation of Concrete Degradation Depending on Heating Conditions by Ultrasonic Pulse VelocityŌĆØ, Construction and Building Materials, Vol. 171, pp. 511-520 (2018), https://doi.org/10.1016/j.conbuildmat.2018.03.178.

15. H. Mohammadhosseini, F. Alrshoudi, M. Md. Tahir, R. Alyousef, H. Alghamdi, Y. R. Alharbi and A. Alsaif, ŌĆ£Performance Evaluation of Novel Prepacked Aggregate Concrete Reinforced with Waste Polypropylene Fibers at Elevated TemperaturesŌĆØ, Construction and Building Materials, Vol. 259, pp. 120418No. 2020, https://doi.org/10.1016/j.conbuildmat.2020.120418.

16. M. Saridemir, M. H. Severcan, M. Ciflikli, S. Celikten, F. Ozcan and C. D. Atis, ŌĆ£The Influence of Elevated Temperature on Strength and Microstructure of High Strength Concrete Containing Ground Pumice and MetakaolinŌĆØ, Construction and Building Materials, Vol. 124, pp. 244-257 (2016), https://doi.org/10.1016/j.conbuildmat.2016.07.109.

17. I. Demir, M. G├╝m├╝s and H. S. G├Čk├¦e, ŌĆ£Gamma Ray and Neutron Shielding Characteristics of Polypropylene Fiber-Reinforced Heavyweight Concrete Exposed to High TemperaturesŌĆØ, Construction and Building Materials, Vol. 257, pp. 119596No. 2020, https://doi.org/10.1016/j.conbuildmat.2020.119596.

18. M. Papachristoforou, E. K. Anastasiou and I. Papayianni, ŌĆ£Durability of Steel Fiber Reinforced Concrete with Coarse Steel Slag Aggregates Including Performance at Elevated TemperaturesŌĆØ, Construction and Building Materials, Vol. 262, pp. 120569No. 2020, https://doi.org/10.1016/j.conbuildmat.2020.120569.

19. M. Uysal, K. Yilmaz and M. Ipek, ŌĆ£Properties and Behavior of Self-Compacting Concrete Produced with GBFS and FA Additives Subjected to High TemperaturesŌĆØ, Construction and Building Materials, Vol. 28, No. 1, pp. 321-326 (2012), https://doi.org/10.1016/j.conbuildmat.2011.08.076.

20. U. Dolinar, G. Trtnik, G. Turk and T. Hozjan, ŌĆ£The Feasibility of Estimation of Mechanical Properties of Limestone Concrete After Fire Using Nondestructive MethodsŌĆØ, Construction and Building Materials, Vol. 228, pp. 116786(2019), https://doi.org/10.1016/j.conbuildmat.2019.116786.

21. G. Roufael, A. L. Beaucour, J. Eslami, D. Hoxha and A. Noumow├®, ŌĆ£Influence of Lightweight Aggregates on the Physical and Mechanical Residual Properties of Concrete Subjected to High TemperaturesŌĆØ, Construction and Building Materials, Vol. 268, pp. 121221No. 2021, https://doi.org/10.1016/j.conbuildmat.2020.121221.

22. I. Netinger, I. Kesegic and I. Guljas, ŌĆ£The Effect of High Temperatures on the Mechanical Properties of Concrete Made with Different Types of AggregatesŌĆØ, Fire Safety Journal, Vol. 46, No. 7, pp. 425-430 (2011), https://doi.org/10.1016/j.firesaf.2011.07.002.

23. K. Ak├¦a├Čzo─¤lu and S. Ak├¦a├Čzo─¤lu, ŌĆ£The Effect of Elevated Temperature on the Lightweight Concrete Produced by Expanded Clay Aggregate and Calciaum Aluminate CementŌĆØ, Bilge International Journal of Science and Technology Research, Vol. 1, No. 2, pp. 59-70 (2017), https://dergipark.org.tr/en/pub/bilgesci/issue/32353/342232.

24. W. Yao, J. Pang and Y. Liu, ŌĆ£Performance Degradation and Microscopic Analysis of Lightweight Aggregate Concrete after Exposure to High TemperatureŌĆØ, Materials, Vol. 13, No. 7, pp. 1566No. 2020, https://doi.org/10.3390/ma13071566.

25. M. Z. Jumaat, U. J. Alengaram, R. Ahmmad, S. Bahri and A. B. M. S. Islam, ŌĆ£Characteristics of Palm Oil Clinker as Replacement for Oil Palm Shell in Lightweight Concrete Subjected to Elevated TemperatureŌĆØ, Construction and Building Materials, Vol. 101, pp. 942-951 (2015), https://doi.org/10.1016/j.conbuildmat.2015.10.104.

26. ├¢S Bideci, ŌĆ£The Effect of High Temperature on Lightweight Concretes Produced with Colemanite Coated Pumice AggregatesŌĆØ, Construction and Building Materials, Vol. 113, pp. 631-640 (2016), https://doi.org/10.1016/j.conbuildmat.2016.03.113.

27. H. A. Bengar, A. A. Shahmansouri, N. A. Z. Sabet, K. Kabirifar and V. W. Y. Tam, ŌĆ£Impact of Elevated Temperatures on the Structural Performance of Recycled Rubber Concrete: Experimental and Mathematical ModelingŌĆØ, Construction and Building Materials, Vol. 255, pp. 119374No. 2020, https://doi.org/10.1016/j.conbuildmat.2020.119374.

28. Y. Li, K. Tan and E. Yang, ŌĆ£Influence of Aggregate Size and Inclusion of Polypropylene and Steel Fibers on the Hot Permeability of Ultra-High Performance Concrete(UHPC) at Elevated TemperatureŌĆØ, Construction and Building Materials, Vol. 169, pp. 629-637 (2018), https://doi.org/10.1016/j.conbuildmat.2018.01.105.

29. M. H. Zhang and O. E. Gjorv, ŌĆ£Microstructure of the Interfacial Zone Between Lightweight Aggregate and Cement PasteŌĆØ, Cement and Concrete Research, Vol. 20, No. 4, pp. 610-618 (1990), https://doi.org/10.1016/0008-8846(90)90103-5.

30. Y. Ke, S. Ortola, A. L. Beaucour and H. Dumontet, ŌĆ£Identification of Microstructural Characteristics in Lightweight Aggregate Concretes by Micromechanical Modelling Including the Interfacial Transition Zone (ITZ)ŌĆØ, Cement and Concrete Research, Vol. 40, No. 11, pp. 1590-1600 (2010), https://doi.org/10.1016/j.cemconres.2010.07.001.

31. T. Lee, K. Jeong and H. Choi, ŌĆ£Effect of Thermal Properties of Aggregates on the Mechanical Properties of High Strength Concrete Under Loading and High Temperautre ConditionsŌĆØ, Materials, Vol. 14, No. 20, pp. 6093No. 2021, https://doi.org/10.3390/ma14206093.

32. K. D. Hammer, ŌĆ£Concrete Strength for Fire Safety DesignŌĆØ, Magazine of Concrete Research, Vol. 57, No. 8, pp. 445-453 (2005), https://doi.org/10.1680/macr.2005.57.8.445.

- TOOLS

-

METRICS

-

- 0 Crossref

- 283 View

- 17 Download

- Related articles in Int J Fire Sci Eng.

-

The Engineering Properties of Concrete Exposed at High Temperature2004 March;18(1)

Microstructure Characteristics of Concrete Exposed to High Temperature1998 December;12(4)