|

|

- Search

| Int J Fire Sci Eng > Volume 37(2); 2023 > Article |

|

Abstract

In the early stage of a fire, sprinklers system of water-based fire-extinguishing systems, which are harmless to the human body, are the most widely used for fire control and suppression in manufacturing factories. The logistic carrier transport in modern manufacturing companies has been almost fully automated and sprinklers are installed around them all over the world. In the presence of an obstruction, a base plate around the upper logistic rail secures the separation distance from the obstacle of more than three times the width of the obstacle, as required by fire regulations (National Fire Technical Code 103 and National Fire Protection Association 13). However, if this cannot be achieved, the fire sprinkler should be more than 600 mm from the base plate, and the opening ratio of the base plate should be less than 70% in an upper logistic rail. This requires sprinklers to be positioned away from obstructions at a minimum of three times the maximum dimension of the obstruction. This study analyzed the sprinkler discharge obstruction from the base plate around the upper logistic rail using the UL standard for sprinkler water spray for the logistic rail area of manufacturing factories. The results can contribute to mitigating fire risks and safety problems.

A sprinkler system, a water-based fire-extinguishing system, is harmless to the human body and uses a high specific heat and latent heat of evaporation based on the accessibility of available water. It is most commonly used for fire control and suppression during the early stages of fires to protect human life and properties.

However, even highly reliable equipment cannot achieve the required performance if structural obstacles exist around the sprinkler. In the presence of obstacles, fire control and suppression would be difficult, resulting in damage to human life and property. Because of the importance of the impact of obstacles around the sprinkler, some countries such as the United States, provide detailed specifications for sprinkler installation to avoid obstructing the fire extinguisher.

Therefore, efforts are being made to prevent discharge obstructions. In particular, the National Fire Protection Association (NFPA) has researched the discharge obstruction of sprinklers for several years, revising and supplementing relevant regulations and continuing to study their adequacy. However, worldwide, fire safety standards for sprinkler discharge obstructions in manufacturing companies, whether appropriate or not, have not been studied to date.

Therefore, this study compared the discharge obstruction rules for sprinkler installation stipulated in the National Fire Safety Standard in Korea with the fire safety standard NFPA 13 (2019) of the United States, an advanced fire-protection country, and the National Fire Technical Code (NFTC) 103. We identified and simulated discharge obstruction problems, with the following method: First, the results of previous studies related to sprinklers were reviewed with reference to the theoretical study of discharge obstruction. Second, domestic discharge obstruction standards for sprinkler facilities within fire safety standards (NFTC 103) were compared with the advanced NFPA to review the adequacy of the standards for preventing discharge obstruction. Third, important factors such as water pressure, separation distance (SD), and spray distribution performance in manufacturing buildings were investigated.

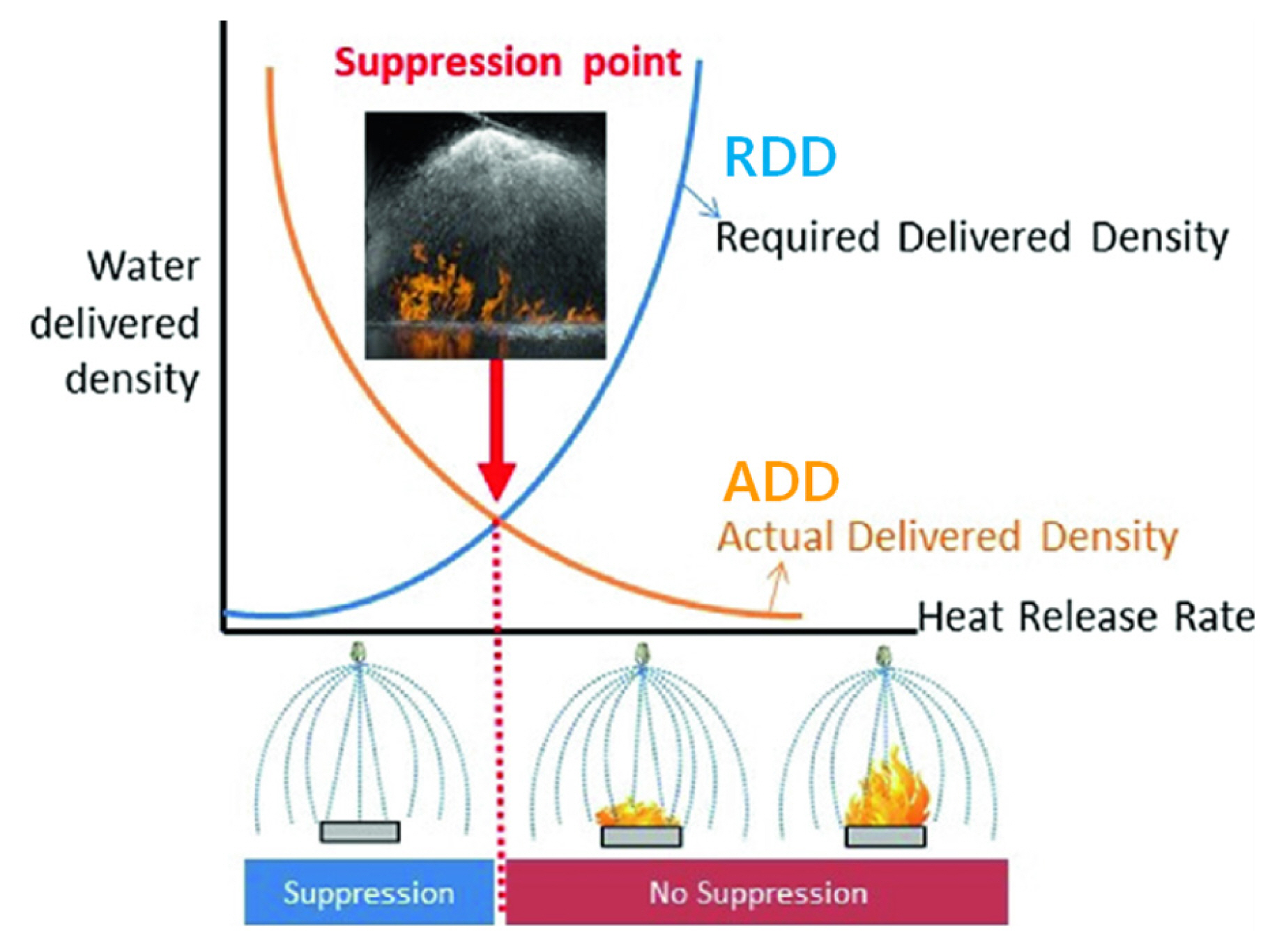

The radiation density for fire extinguishing is divided into the actual delivery density (ADD) and required radiation density (RDD). The obstacles around the sprinkler should be smaller than the RDD, which requires the ADD to extinguish the fire by reflecting sprinkler water from a waterproof point to a place other than the fire surface, or by reducing the droplet size [1].

However, control may fail (Figure 1). When an object or structure prevents the pattern of water emitted from the sprinkler from forming properly or reduces the radiation density, it can be defined as a discharge obstruction. In the case of a fire, sprinklers should be located in a hot-gas layer that expands near the ceiling. In particular, the ceiling structure affects the installation and function of the sprinkler because it determines the position and permissible protective area of the sprinkler. For quick operation in a fire, the sprinkler must be installed at a certain distance from the ceiling, depending on the type of ceiling structure. In addition, ceiling sprinklers should be installed such that they do not adversely affect the watering pattern [1,2].

The discharge coefficient, commonly referred to as the K-factor, is the rate at which water is delivered through a sprinkler as a function of the inlet pressure. It is determined empirically by measuring the water flow rate and water pressure at the sprinkler inlet and then performing the following calculation [5]:

where

K = Discharge coefficient (K-factor) in gpm/psi1/2

Q = Flow rate in gpm

P = Pressure in psi

Two standards are used for sprinkler spray distribution tests in Korea: The Korea Fire Institute (KFI) standard satisfies the average water collection (mm/min); however, the UL standard requires two conditions to satisfy the average and minimum water collection. The UL standard stipulates that all pans must achieve a minimum density of 75% of the required average valves. The UL standard limits for sprinkler water sprays are listed in Table 1. The minimum water collection is 75% of the average water collection. As the water spray test for the SD is more stringent than the domestic test conditions (KFI), it was applied in this study.

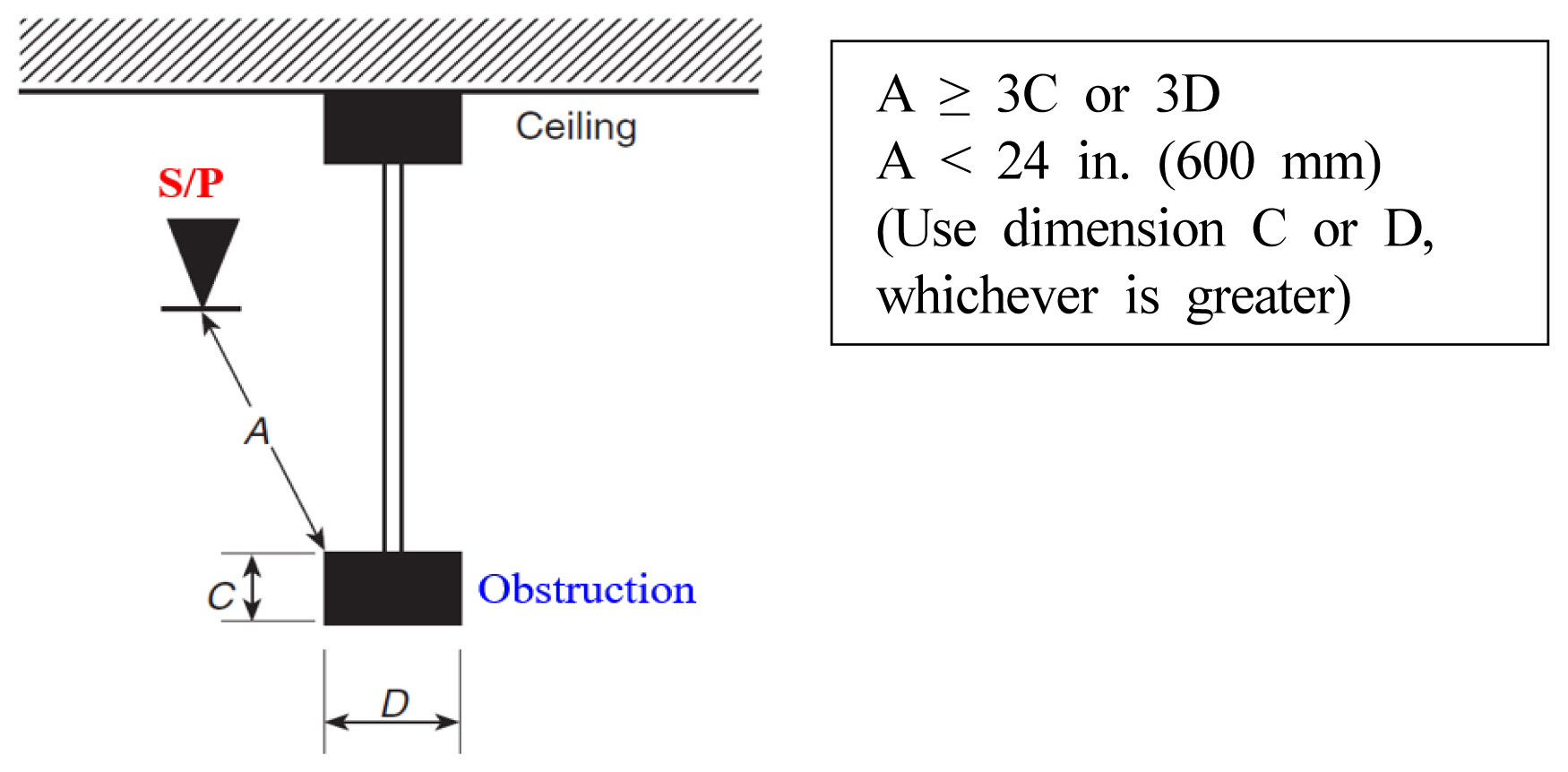

NFPA 13 (2019) section 10.2.7.2.1.3 details the "three times rule," which states that unless specific requirements are satisfied, "sprinklers shall be positioned away from obstructions at a minimum distance of three times the maximum dimensions of the obstruction," up to a maximum of 24 in., although the "maximum clear distance does not apply to obstructions in the vertical orientation (e.g., columns)." Table 2 compares the domestic discharge obstruction standards for sprinkler facilities within the fire safety standard (NFTC 103) and the advanced NFPA to review the adequacy of the discharge obstruction prevention standards. In NFPA 13, the SD from sprinklers to the side of the obstruction is divided into 14 steps [7,8].

The efficiency of sprinklers is significantly reduced when the water discharged does not reach the fire ignition point. The point of discharge obstruction can complicate fire control or suppression (Figure 2(a)). The base plate of an upper logistic rail secures the SD from the obstacle at more than three times the width of the obstacle, in compliance with fire regulations (NFTC 103 and NFPA 13). If this cannot be satisfied, the base plate should be more than 600 mm from the fire sprinkler and separated from the obstacle. According to fire regulations, if the obstacle and SDs (600 mm) are not satisfied, the opening ratio must exceed 70%. If this is not possible, the opening ratio (30%-36%) of the base plate should be less than 70% in the manufacturing plants. This requires the sprinklers to be positioned at least three times the maximum dimension of the obstruction.

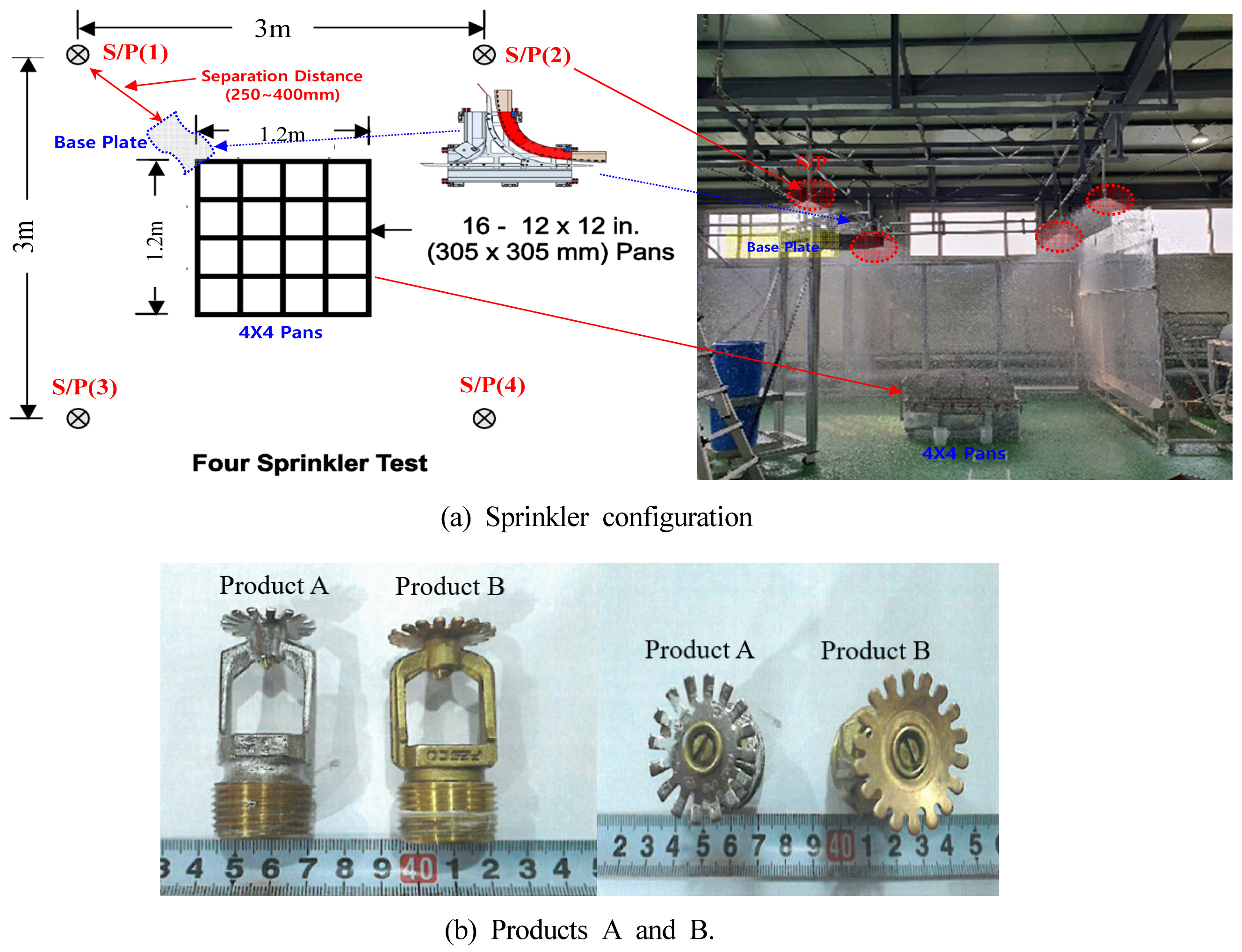

The UL sprinkler standards contain tests for evaluating the capability of sprinklers in controlling or suppressing fires. These standards also include a broad range of tests to investigate the ability of sprinklers to operate and perform as intended under stressed and adverse field conditions. In these tests, water discharge from four sprinklers is collected in 16 pans, positioned as shown in Figure 3. The sprinklers are randomly selected and installed with frame arms parallel to the branch-line pipe. The repositioning of sprinklers, or the placement of specific sprinklers in specific locations, is not permitted. Each sprinkler should distribute water at a rate of 79.4 L/min and water should be collected for at least 3 min. This study simulated sprinkler water spray for a base plate with a maximum opening ratio of 33% (Figure 2(b)), and a pendant sprinkler was analyzed according to the water pressure (0.05-0.1 MPa) and SD (250-400 mm) for two types of products.

The water spray characteristics of a sprinkler significantly affect the fire suppression performance, and they are largely dependent on the SD and water pressure [11].

This study investigated the water pressure and SD performances of sprinklers of two domestic companies with large-market sprinklers. The experimental results at 0.1 MPa revealed that both products (A and B) satisfied the UL standard limits. However, differences were observed between the two types of products, as shown in Table 3. A spray distribution experiment was conducted by adjusting the SD between no-obstacle and obstacle conditions to 250-400 mm. The performance standards relating to the amount of water collected satisfied the SD at a water pressure of 0.1 MPa according to the fire safety standards.

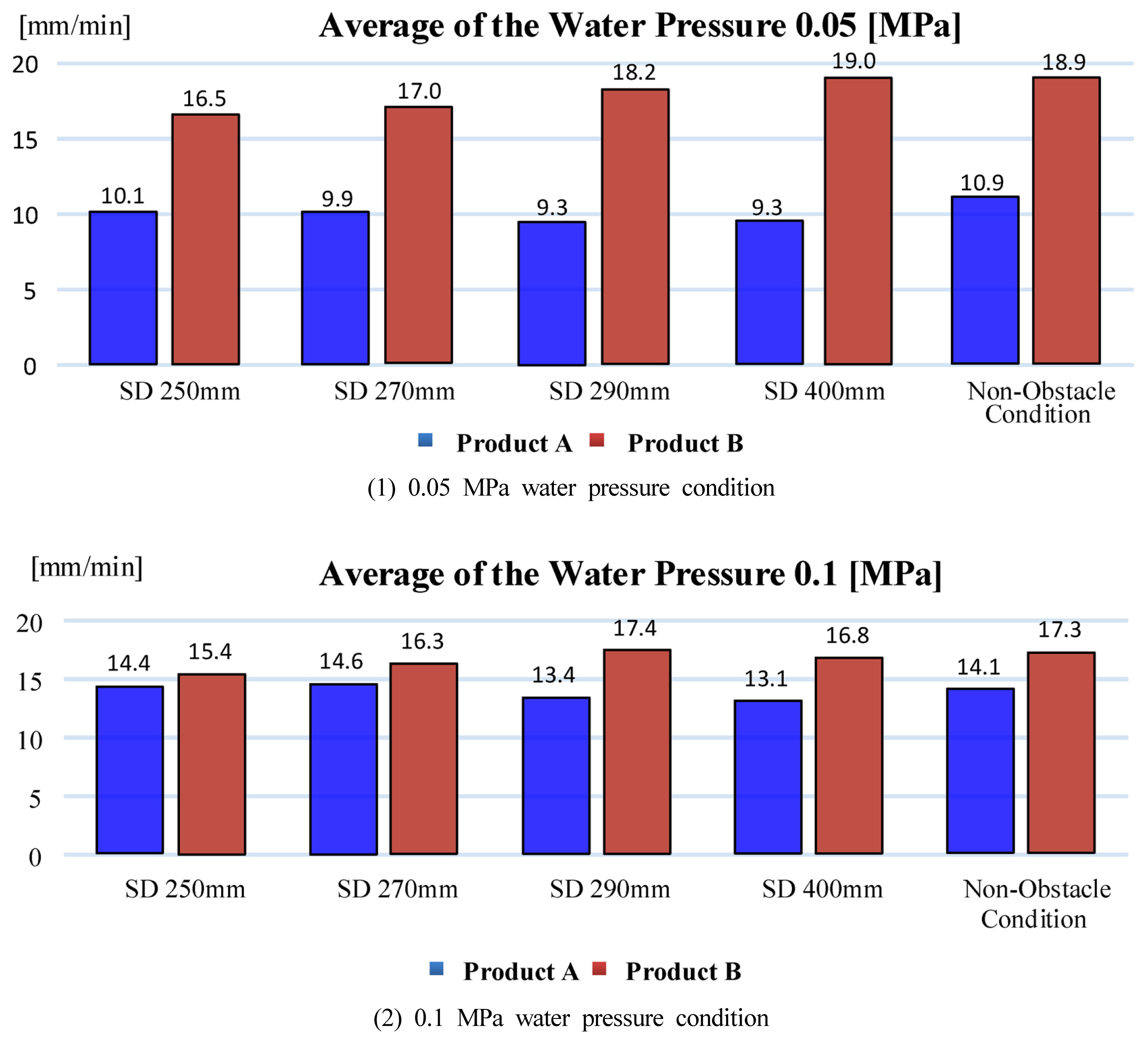

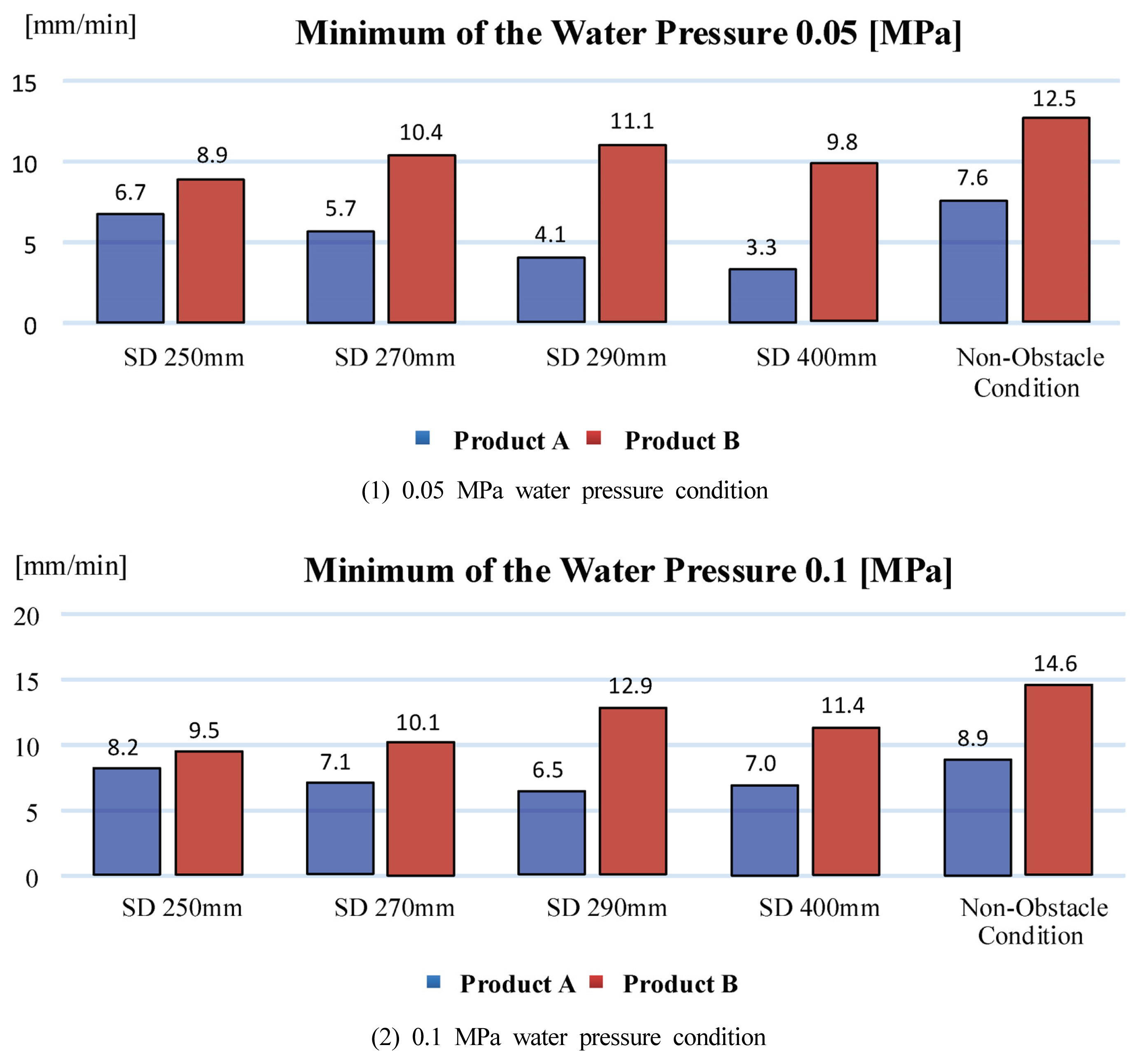

Figure 4 shows the average water collection for products A and B under identical water pressure conditions. The experimental results of the average water collection test satisfied the minimum 8.9 mm/min required in the UL standard. Additionally, no problems associated with sprinkler discharge obstruction occurred. The test results showed that the average water collection of product B was larger than that of product A. Product B performed better than product A in terms of its ability to spray water.

Figure 5 shows the minimum water collection for products A and B under identical water-pressure conditions. The results of product B satisfied the minimum water collection test of 6.675 mm/min of the UL standard, whereas those of product A did not. The shape of the sprinkler head interfered with most discharge obstructions when the actual SD was 270-400 mm. These experimental results could not be explained logically.

Tests were repeated using the sprinkler distribution test of the UL sprinkler standards with discharge obstructions produced water collection results with similar valves. The experimental results revealed considerable variation between the water pressure conditions achieved under identical conditions for sprinkler discharge obstruction.

In the presence of an obstruction, a base plate of upper logistic rails secures the separation distance from an obstacle of more than three times the width of the obstacle, as required in fire regulations (NFTC 103 and NFPA 13). If this cannot be achieved, the fire sprinkler should be more than 600 mm from the base plate, and the opening ratio of the base plate should be less than 70%. In this study, a spray distribution test was used to analyze the sprinkler discharge obstruction from the base plate using the UL standard for sprinkler water sprays. The discharge obstruction of the sprinkler stipulated in the local fire safety standard was compared with the US fire safety standard NFPA 13 (2019) and NFTC 103. The separation distance from the sprinklers to the side of the obstruction was divided into 14 steps based on NFPA 13. The water spray characteristics of sprinklers significantly affect fire suppression performance, and they are largely dependent on the separation distance and water pressure.

Tests conducted using the sprinkler distribution test of the UL sprinkler standards with discharge obstructions produced water collection results with similar valves. The experimental results revealed a considerable variation between the water pressure conditions achieved under identical conditions for sprinkler discharge obstruction. This study analyzed the sprinkler water spray for an opening ratio of less than 70% of sprinkler discharge obstruction, which contributes to fire risks and safety problems.

Notes

Author Contributions

Conceptualization, methodology, J.-H.K. and H.-S.K.; validation, H.-S.K. and S.-C. L.; formal analysis, H.-S.K. and J.-H.K.; data curation, H.-S.K.; WritingŌĆöOriginal draft preparation, J.-H.K. and S.-C. L.; WritingŌĆöReview and editing, J.-H.K. and S.-C. L.; supervision. All the authors have read and agreed to the published version of this manuscript.

Table┬Ā1

| K-factor | Water Flow per Sprinkler | Average Water Collection | Minimum Water Collection | |||

|---|---|---|---|---|---|---|

| gpm | L/min | gpm/ft2 | mm/min | gpm/ft2 | mm/min | |

| 8.0 | 21.000 | 79.400 | 0.2100 | 8.900 | 0.1575 | 6.675 |

Table┬Ā2

Table┬Ā3

Simulation Results of Sprinkler Discharge Obstruction

References

1. Iqbal and M.H. Salley, ŌĆ£Fire Dynamics Tool(FDT):Quantitative Fire Hazard Analysis Methods for the U.S. Nuclear Regulatory Commission Fire Protection Inspection ProgramŌĆØ, NUREG-1805, U.S. Nuclear Regulatory Commission, (2004).

2. Y. H. Kwon and S. H. Min, ŌĆ£Application of Sprinkler Discharge Obstruction in Manufacture FactoriesŌĆØ, Journal of the Korean Society of Hazard Mitigation, Vol. 21, No. 2, pp. 97-102 No. 2021.

3. D. R. Hague and C. R. W. Duffy, ŌĆ£Automatic Sprinkler Systems HandbookŌĆØ, 14th ed., NFPA, Massachusetts (2019).

4. P. Brown, ŌĆ£Obstruction Rules for CMSA SprinklersŌĆØ, Sprinkler Age, (2015).

5. Underwriters Laboratory, ŌĆ£UL199 Automatic Sprinklers for Fire-Protection ServiceŌĆØ, 12th ed., (2020).

6. S. Jordan, J. Geiman, R. Bentley and N. Ryder, ŌĆ£Impact of Sprinkler K-Factor and Operation Pressure on Sprinkler Spray Discharge Characteristics and Spray PatternsŌĆØ, Fire Protection Research Foundation, (2019).

7. S. H. Kim and S. S. Lee, ŌĆ£A Study on Improvement of Discharge Obstruction Prevention Standard for Sprinkler on NFSC 103ŌĆØ, Journal of the Society of Disaster Information, Vol. 16, No. 2, pp. 237-247 No. 2020, https://doi.org/10.15683/kosdi.2020.06.30.237.

8. Korea Fire Institute (KFI), Type Approval and Product Inspection Testing Details of Sprinkler Head, (2018).

9. NFPA 13, ŌĆ£Standard for the Installation of Sprinkler SystemsŌĆØ, National Fire Protection Assoication, Quincy, MA (2019).

10. NFTC 103, ŌĆ£Standard for the Installation of Sprinkler SystemsŌĆØ, National Fire Science Research Center (2021).

11. S. J. Lee and D. M. Lee, ŌĆ£An Experimental Study on the Separation Distance to Prevent Impairment of Sprinkler SprayŌĆØ, Journal of the Korean Society of Hazard Mitigation, Vol. 22, No. 5, pp. 125-131 No. 2022, https://doi.org/10.9798/KOsprinklerAM.2022.22.5.125.

- TOOLS

-

METRICS

-

- 0 Crossref

- 776 View

- 16 Download

- Related articles in Int J Fire Sci Eng.

-

Spray Characteristics Analysis of Fire Sprinkler Spray with Image Processing2023 September;37(3)